How Electronic Adhesives Improve Reliability in High-Performance Devices

Technology has transformed how people interact with the world, but its impact relies on the durability and precision of the devices used daily. Every component must work seamlessly under pressure, from smartphones to medical equipment and aerospace systems. Electronic adhesives provided by reputed manufacturers ensure that equipment functions and endures extreme conditions over time.

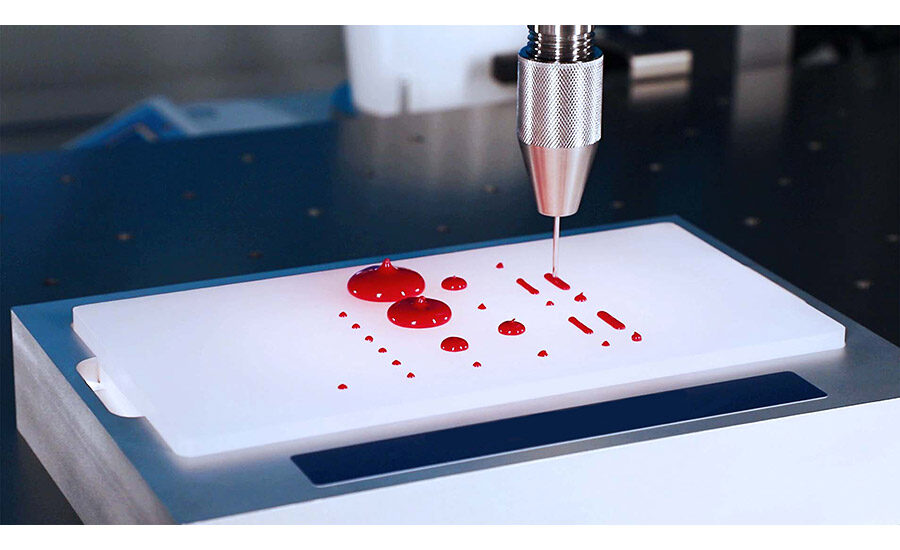

The Unsung Heroes of Modern Electronics

The bonding agents for electronics are overlooked, yet they hold together the most vital components of high-performance gadgets. Unlike traditional fastening methods, these specialized bonding solutions offer strength, flexibility, and conductivity. An electronic adhesive manufacturer focuses on developing formulas that cater to various industry needs, from microchips in mobiles to circuit boards in industrial machinery. These solutions enhance reliability by preventing component failure caused by vibration, thermal expansion, or environmental exposure.

Enhanced Durability in Harsh Conditions

High-performance units operate in areas where extreme temperatures and humidity pose serious risks. If components are not adequately secured, condensation can lead to corrosion, and temperature fluctuations can cause materials to expand and contract, weakening connections over time. Electronic sealant provided by a reliable manufacturer acts as a protective barrier, sealing out moisture and preventing damage caused by thermal cycling. By creating a stable bond that can withstand heat and humidity, the adhesive extends the lifespan of critical electronic parts and ensures uninterrupted performance.

Vibration and Shock Resistance

Many devices, from aircraft control systems to automotive electronics, are constantly subjected to movement, impact, and vibration. Traditional mechanical fasteners, such as screws and solder joints, can loosen or crack under these conditions, leading to device failure. The bonding agents offer a flexible yet firm bond that absorbs vibrations and reduces stress on delicate components. This elasticity prevents microfractures in solder joints, allowing electronics to maintain functionality even in the most demanding applications.

Smaller, Lighter, and More Efficient Devices

As consumer expectations push for thinner and lighter systems, manufacturers must reduce bulk without sacrificing performance. Traditional assembly methods add unnecessary weight and take up valuable space. Modern electronic sealants provide a solution by eliminating the need for bulky screws, brackets, and welds. This allows designers to create sleeker, more compact products without compromising structural integrity. Specific binders are designed with heat-dissipating properties, ensuring that excess warmth is evenly distributed rather than trapped within it. This improves overall efficiency, reduces the risk of overheating-related failures, and improves battery life in portable electronics.

Meeting the Demands of Emerging Technologies

The rise of wearable health monitors, implantable medical devices, and next-generation hearing aids has heightened the demand for biocompatible epoxies provided by authentic manufacturers. These applications require bonding solutions safe for prolonged skin contact and resistant to bodily fluids. Adhesives used in medical electronics provide strong bonds and ensure that devices remain comfortable and secure for users. Their ability to withstand sweat, movement, and temperature changes makes them indispensable in healthcare.

Supporting the Growth of 5G and IoT

The expansion of 5G networks and the Internet of Things (IoT) has introduced new performance expectations for electronic gadgets. Faster data speeds and continuous connectivity require components that can handle increased power loads and environmental exposure. Specialized binders manufactured by renowned companies help secure antennas, sensors, and microchips while enhancing conductivity and thermal management. This ensures that 5G-enabled and IoT-connected machines remain reliable, even under heavy usage. The reliability of high-performance machines depends on more than advanced engineering—it requires materials that reinforce their strength and longevity. Electronic sealants, which provide durable, lightweight, and conductive bonding solutions, have become essential in consumer electronics and aerospace industries.

Also read: Finances in Order

More businesses are looking to integrate high-quality compounds into their manufacturing processes. Partnering with an electronic adhesive manufacturer ensures access to cutting-edge solutions designed for demanding applications. As technology evolves, these bonding innovations will remain the mainspring of reliability and performance.