Photoelectric Sensors: Accurate Detecting in Today’s Factories

As factories and warehouses grow more high-tech, fast and reliable ways to spot moving parts are a must. Photoelectric sensors have become one of the go-to tools for businesses in fields like shipping, bottling, food prep, and car assembly lines. Because they use light rather than touch to sense objects, these sensors work at a distance and keep machinery running smoothly without mechanical wear.

This post will walk you through how photoelectric sensors actually do their job, the different types you might find in the field, where they are commonly used, and what advantages they bring. We’ll also share tips on picking the right model for your set-up and show how trusted brands such as OMCH back their partners with sturdy parts and smart add-on systems.

How Photoelectric Sensors Do Their Job

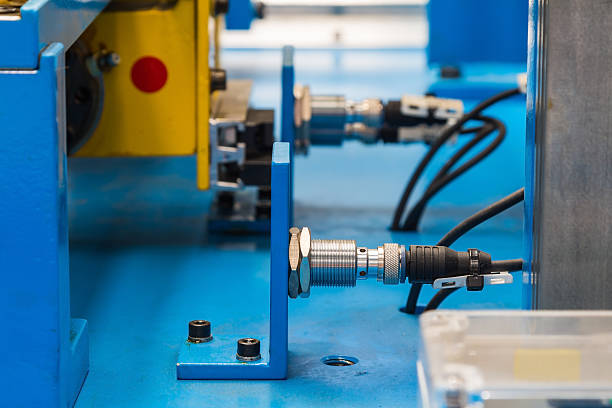

Inside every photoelectric sensor sits a tiny light source, usually infrared or a visible red beam, paired with a matching receiver. When something interrupts the beam or reflects the light in a new pattern, the receiver notices the shift and sends out an on or off signal. Because the detection happens without physical contact, these sensors can work reliably at ranges from a few millimeters all the way up to several meters.

Photoelectric sensors are handy devices that let machines “see” without needing a camera. There are three common setups you’ll find in factories or on production lines.

First up are through-beam sensors. Here, the light source and the receiver sit in two separate boxes, often placed several meters apart. When a person, box, or any object steps in front and blocks the light, the circuit closes and the system reacts. This method works great outdoors or in dusty places because it only needs a clean break in the beam to function.

Next is the retroreflective sensor. In this setup, both the transmitter and receiver share one housing, while a small mirror or reflector fixed somewhere down the line bounces the light back. As soon as something passes between the sensor and the reflector, the returning light is cut off and the device sends a signal. Retroreflective sensors are popular in cramped spaces where it’s hard to run long cables.

Finally, we have diffuse-reflective sensors. Here again, both parts live inside a single unit, but instead of looking for light that bounces back from a separate reflector, they wait for light that reflects off the object itself. The sensor “decides” something is present if enough light returns, making these handy for items of varying color and texture that sit close to the sensor.

Choosing the right type really depends on the distance you need, the surface of the target, and the kind of space the sensor will live in. For buyers looking to pair these sensors with solid controls, checking out something like the https://www.omchsmps.com/es/categoria-producto/ssr-relay/ can add extra reliability to the whole system.

How Photoelectric Sensors Power Modern Industry

Photoelectric sensors may look simple, but they are the unsung heroes of many factories and warehouses. These light-based eyes let machines “see” what’s happening in real time, so industries that depend on counting, positioning, or quick detection rely on them. Here are a few places you’ll find them working hard every day.

Packaging and Bottling Lines

Think about the last bottle of soda or jar of sauce you bought. Long before it reaches the store, photoelectric sensors are at work on the assembly line. They spot whether a bottle is present on a moving belt, double-check that labels are lined up just right, and even make sure that each container is filled to the proper mark. Because these sensors can react in the blink of an eye and still “see” objects from several feet away, the entire process stays quick and problem-free.

Robotics and Motion Systems

In modern factories, robotic arms are often doing heavy lifting and precise placements. Here, photoelectric sensors act like guiding lights. They help the robot know exactly where an item is resting, trigger the next pick-and-place movement, and keep machinery from bumping into things it shouldn’t. This pinpoint accuracy reduces costly mistakes, speeds up assembly, and makes material handling run like clockwork.

Food and Beverage Industry

Food production lines must meet strict cleanliness standards, so not every type of sensor will do. Specialized photoelectric sensors made for washdown areas keep spotting trays of fruit, cartons of juice, or stacks of plastic bottles—even when water jets are blasting the equipment. Standard sensors sometimes struggle with clear or shiny surfaces, but photoelectric models are clever enough to see through shrink-wrap or recognize faint outlines, making them a popular choice in this sector.

Warehouse Automation

Today’s logistics hubs are buzzing with automated systems that move goods from truck to shelf without much human help. Inside these vast warehouses, photoelectric sensors are wired into automated storage and retrieval systems, conveyor tracks, and high-tech parcel sorters. They tell the system whether a box has arrived, measure how fast packages are passing by, and help direct each item to the right lane. Thanks to these sensors, order processing speeds up, backlogs shrink, and inventory stays accurate.

Automotive and Electronics Manufacturing

Across modern production lines, photoelectric sensors quietly do the heavy lifting. Whether it’s checking that a part is the right shape, guiding it into place, or double-checking that components fit together perfectly, these little eyes make sure nothing is out of alignment before the next stage kicks in.

Why B2B Automation Loves Photoelectric Sensors

When factories have to choose a detection system, photoelectric sensors often win—especially when the job isn’t a simple metal part. Here’s what they bring to the table.

- Impressive Range: Unlike many other sensors, these can spot an item several meters away. That’s a game-changer on big machines or long conveyor belts.

- No Touch, Less Trouble: Because they detect without ever making contact, there’s almost zero wear and tear. That means fewer repairs and longer life before they need replacing.

- Sees Everything: Plastic, glass, paper, metal, fabric—you name it. Color and finish don’t really matter; the sensor picks it up anyway.

- Fast Enough for Formula One: Production lines don’t wait, and neither do these sensors. They keep pace so you won’t bottleneck the next step.

- Fits Just About Anywhere: Tight corners and cramped compartments are no problem. The small, slim designs can slide into places bulkier sensors can’t.

By adding photoelectric sensors to their setups, B2B businesses boost speed, cut costly downtime, and lift the quality of what rolls off the line.

read more : So You Wanna Be an Influencer? Here’s What Nobody Tells You

Picking the Perfect Photoelectric Sensor

Shopping for a photoelectric sensor can feel a little overwhelming because there are so many options on the market today. To help B2B buyers and engineers make a smart choice, keep these important points in mind:

- Sensing Distance: Start by measuring how far the sensor will be from the object it needs to detect. Through-beam sensors usually work over the greatest distance, while diffuse sensors are best when the object is fairly close.

- Target Features: Think about the size, shape, color, transparency, and shininess of the object. These details affect how well the sensor will pick it up.

- Installation Space: Check how much room you have for the sensor and whether it needs to be mounted from the side or the front of a machine.

- Shop Conditions: If the sensor will be in a dusty, steamy, or wet area—or if sunlight will shine directly on it—look for models that have built-in filters or sturdy protective covers.

- Speed of Detection: Make sure the sensor can trigger quickly enough for your application, especially if you’re working with fast-moving production lines.

- Output Compatibility: Finally, verify that the output signal—whether NPN, PNP, analog, or relay—matches the control system or PLC you use.

Many modern sensors also come with features like adjustable sensitivity, background suppression, or teach-in modes that make setup a lot easier.

Working with a reliable supplier like OMCH, which offers detailed datasheets, hands-on support, and a complete range of automation parts, makes it much simpler to pick the right sensor and get everything working together smoothly.

How OMCH Makes B2B Automation Easier with Smart Sensors and Controls

OMCH is well-known in industry circles for making sensors and automation gear that just work. Their lineup, which includes everything from photoelectric eyes to proximity switches and solid-state relays, gives system builders, equipment makers, and factory crews the sturdy, flexible, and affordable tools they need to keep production lines humming.

Take their photoelectric sensors, for example. They come packed with features that matter on the shop floor, like:

- Tough ingress protection ratings (IP65/IP67) that laugh in the face of dust and splashes

- Slim designs that fit where space is tight, such as on small brackets or crowded panels

- Reliable performance even when the workshop lights flicker or the sun streams through a window

- Quick alignment and straightforward mounting holes that save time during installation

OMCH doesn’t stop at sensing. Their full range of solid-state relays handles high-speed switching duties, making them perfect for control boards and distributed I/O stations. You can check out their entire SSR relay product catalog, and you’ll see how well these relays match up with the outputs from photo eyes for seamless operation.

By zeroing in on what B2B partners really need—less downtime and smoother workflows—OMCH makes it simple to source reliable components for both massive builds and one-off automation tasks.

Wrapping it Up

Photoelectric sensors have become cornerstones of today’s industrial automation world. Because they can spot objects quickly, accurately, and without touching the material, they keep production lines running smoothly. Their ability to work well with different surfaces and in tricky environments—plus their long detection distances and proven durability—is why so many engineers choose them.

If you’re setting up a new packaging line, fine-tuning warehouse robotic vehicles, or upgrading an assembly arm, picking the right sensor is a key step you can’t skip. When you team up with a supplier like OMCH, you gain access not only to high-quality hardware but also to the expert advice and support that industrial setups demand.