Profile Wrapping Applications: Interior & Exterior Uses

Have you ever wondered how intricate designs and seamless finishes are achieved on furniture, walls, or exterior surfaces? What techniques allow manufacturers to transform plain materials into something elegant and unique? From advanced coating methods to precise material applications, these processes shape the final product’s aesthetic and durability.

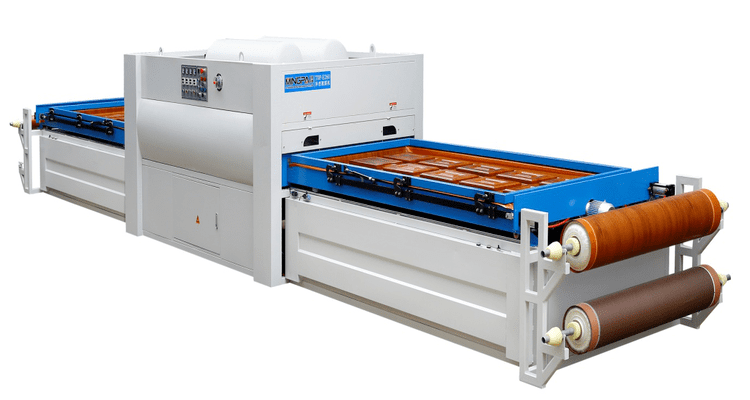

The answer often lies in the process of applying laminates, veneers, and finishes to a variety of substrates. This technique, also known as profile wrapping, creates durable and visually appealing surfaces that can be used in numerous settings. There are countless options for both residential and commercial environments. Let’s explore how this process can elevate both interior and exterior design.

Enhancing Interiors with Laminates and Veneers

Interior design thrives on creativity and customization. Laminates, real wood veneers, and stainable veneers allow designers to add depth and sophistication to any space. For example, cabinets, doors, and furniture often benefit from these materials because they offer durability and aesthetic appeal.

Laminates provide a sleek, modern look and are available in an array of colors and textures. Real wood veneers, on the other hand, bring warmth and authenticity to the design. Whether for walls or furniture, these finishes make interiors feel inviting and luxurious. They’re also easy to maintain, making them ideal for busy households and commercial interiors.

Outdoor Durability with Vinyl and Acrylic

Exterior applications demand materials that can withstand the elements. Vinyl and acrylic finishes are particularly popular for this reason. These coatings are not only weather-resistant but also provide excellent UV protection, ensuring the colors remain vibrant for years.

Doors, windows, and exterior panels often feature vinyl or acrylic layers to improve their performance. This approach doesn’t just protect surfaces; it enhances their visual appeal, too. With options to mimic wood grain, stone, or solid colors, vinyl and acrylic bring style and substance to outdoor spaces.

Creative Uses for Paper Veneers

- Intricate Detailing & Cost-Effective Design

Paper veneers are ideal for creating intricate patterns and designs without high costs. They bring sophistication to projects while remaining budget-friendly. - Lightweight & Easy Application

These veneers are lightweight, making them simple to handle and apply. They work well for smaller projects or detailed decorative accents. - Perfect for Moldings, Trim, & Furniture

Paper veneers can be used on moldings, trims, and furniture to achieve a polished and refined look. They eliminate the need for heavy or cumbersome materials. - Eco-Friendly Solution

For those seeking sustainable options, paper veneers offer an environmentally conscious choice. They reduce waste and use fewer resources compared to traditional materials. - Versatility in Patterns & Finishes

With a wide range of patterns and finishes available, paper veneers enable designers to experiment with creative ideas that other materials may not easily achieve.

Stainable Veneers for Personalized Finishes

Stainable veneers are a designer’s dream when it comes to achieving a custom look. They can be stained in any shade, allowing homeowners and businesses to match existing décor seamlessly. From rich mahogany tones to light oak finishes, the options are virtually limitless.

These veneers are often used in high-end furniture and cabinetry because they give a natural, high-quality finish. Additionally, they’re perfect for anyone who wants to add their personal touch to a project, as staining allows for complete control over the final appearance. Their versatility also makes them an excellent choice for modern and traditional design styles alike.

Also read: Roofing Materials

From the cozy interiors of a home to the rugged exteriors of a commercial building, the applications of these innovative finishes are vast. Profile wrapping combines craftsmanship and technology to create materials that are both functional and beautiful. It’s a process that allows designers and manufacturers to push boundaries, transforming ordinary surfaces into extraordinary designs.