Working Principle and Mechanical Mechanism of Lifting Equipment

Fundamental Working Principles of Lifting Equipment

Lifting equipment operates on specific principles that allow you to move heavy loads safely and efficiently. Understanding these principles can help you appreciate the technology behind various lifting devices.

Mechanical Advantage and Force Multiplication

Mechanical advantage is a key concept in lifting equipment. It allows you to lift heavier loads with less effort. This advantage comes from using simple machines like pulleys and levers.

For example, a pulley system can reduce the amount of force needed to lift a load. If you use multiple pulleys, the effort needed decreases significantly. A common formula is:

Mechanical Advantage (MA) = Load Force / Effort Force

This simple ratio shows how efficiently a machine can multiply force. Knowing how to apply this can improve your lifting tasks.

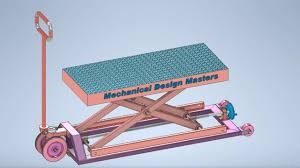

Basic Lifting Mechanisms

Various lifting mechanisms are used in machinery. These mechanisms include hoists, cranes, and elevators. Each has a unique way of lifting loads.

Hoists typically use a combination of gears and pulleys. They lift items vertically, and their operation can be manual or powered. Cranes have long arms that extend to move loads horizontally and vertically. Elevators employ a system of cables and pulleys to transport people or goods between floors.

Understanding these mechanisms helps in choosing the right equipment for your needs.

Role of Torque and Rotary Motion

Torque is essential for lifting equipment that uses rotary motion. It refers to the rotational force applied around an axis. In lifting applications, machines like winches and cranes rely on torque to lift loads efficiently.

When you apply force to a handle or switch, the resulting torque turns gears or pulleys. This motion translates into upward movement. The effectiveness of this process depends on the size of the wheel or gear. The bigger the gear, the less force you need to apply.

By mastering torque and understanding rotary motion, you can optimize lifting performance.

Mechanical Mechanisms in Lifting Equipment

Understanding the mechanical mechanisms in lifting equipment is essential for safe and effective operation. This area covers the various systems that work together to lift and move heavy loads efficiently.

Transmission System and Moving Parts

The transmission system is vital in lifting equipment. It transfers power from the engine to the moving parts. Common components include gears, belts, and chains, which help control the movement of the machinery.

Key components of the transmission system:

- Gears: Adjust the speed and torque.

- Belt Drives: Provide smooth motion with less noise.

- Chains: Offer strength and durability for heavy loads.

Each part plays a role in ensuring your equipment operates smoothly and efficiently. Regular maintenance of these components is crucial to prevent breakdowns.

Booms, Jibs, and Arms

Booms and jibs are important parts of cranes and other lifting machines. They act as extensions, reaching out to lift loads. The boom is typically a long arm, while the jib adds extra support and flexibility.

Types of extensions:

- Booms: Fixed or telescoping to reach different heights.

- Jibs: Adjustable for various angles to improve lifting range.

These components work together to increase the versatility of lifting equipment. This design helps you lift higher or reach further, making your work easier.

Control System and Monitoring

The control system is where you manage your lifting equipment. It includes levers, buttons, and electronic controls that allow you to operate machinery confidently. Monitoring devices ensure safety and efficiency during operation.

Key features of the control system:

- Limit Switches: Prevent overloading and reduce risks.

- Sensors: Provide real-time information on weight and position.

- Remote Controls: Offer ease of operation, especially for large machinery.

Regular checks on these systems help maintain safety and efficiency, ensuring that everything runs smoothly while you work.

Hydraulic Mechanisms and Operation

Hydraulic mechanisms play a crucial role in lifting equipment by using fluid power to create movement. Understanding how these systems work can help you appreciate their efficiency and reliability in various applications.

Principles of Hydraulic Systems

Hydraulic systems use the movement of fluid to generate power. When you apply force to a fluid, it travels through tubes or hoses to different parts of the machinery. This transfer of fluid pressure allows for lifting and moving heavy objects with minimal effort.

In a hydraulic system, the main components include a reservoir for storage, pumps to move fluid, valves to control flow, and cylinders to convert fluid pressure into mechanical force. When activated, hydraulic lifts can raise or lower loads smoothly and efficiently.

Pascal’s Law and Hydraulic Fluids

Pascal’s Law is a key principle in hydraulics. It states that when pressure is applied to a confined fluid, the pressure changes uniformly in all directions. You benefit from this law when using hydraulic lifts since even a small force can lift a heavy load.

The hydraulic fluid is essential in this system. It is typically oil, chosen for its incompressible nature and ability to transmit force. Other important properties of hydraulic fluids include viscosity and thermal stability. These factors ensure the fluid flows effectively within the system without losing efficiency.

Hydraulic Cylinders and Motors

Hydraulic cylinders are vital parts of hydraulic systems. They convert hydraulic energy into linear motion. When fluid enters the cylinder, it pushes a piston, creating movement. The larger the cylinder, the greater the lifting capacity.

Hydraulic motors, on the other hand, convert hydraulic energy into rotational motion. They work similarly to cylinders but are designed to turn shafts for tasks like driving wheels or belts. Both components are crucial for the functionality of lifting equipment, ensuring it operates smoothly and safely.

Key Components and Structural Requirements

When working with lifting equipment, understanding the essential components and structural elements is crucial. The performance and safety of these machines depend on how well they’re designed and built.

Base, Stability, and Weight Distribution

The base of lifting equipment is vital for its stability. A wider base helps in balancing the load, ensuring the equipment does not topple over. The weight distribution across the base must be even. If weight shifts too much to one side, it can lead to accidents.

Materials used for the base should be strong enough to support heavy loads without bending or breaking. You need to regularly inspect the base to ensure no cracks or defects develop over time.

Strength and Material Specifications

The strength of lifting equipment comes from its materials. Common materials like steel and aluminum are selected for their durability.

Specifications to consider:

- Load Capacity: Know the maximum weight your equipment can handle safely.

- Material Grade: Higher grades offer better strength-to-weight ratios.

Regular checks against these specifications ensure you avoid using equipment that may fail under stress. Always follow manufacturer guidelines for materials and specifications.

Mobility: Crawler Tracks and Terrain

Crawler tracks are essential for moving lifting equipment over various terrains. These tracks provide better grip and stability on soft or uneven surfaces compared to wheels.

Make sure to consider:

- Track Width: Wider tracks provide more stability.

- Terrain Type: Understand what type of surface you’ll be working on, as different tracks perform better on different terrains.

Having equipment suited for your specific work environment can enhance both safety and efficiency. Regular maintenance of crawler tracks helps keep them in top condition.

Power Sources and Performance Factors

When it comes to lifting equipment, understanding power sources and how they affect performance is key. The type of motor you choose and its reliability can have a big impact on how well your equipment works in various conditions.

Electric Motors and Power Transmission

Electric motors are popular choices for lifting equipment due to their efficiency and ease of use. They convert electrical energy into mechanical motion, making operations smooth and predictable.

Key components include:

- AC Motors: Often used for larger, heavy-duty lifting. They provide strong torque.

- DC Motors: Great for precision control and quick response.

Power transmission systems, like gears and pulleys, help adjust the motor output to match lifting needs. Make sure you consider the horsepower and voltage specifications to align with your lifting tasks.

Reliability Under Working Conditions

Reliability is crucial for lifting equipment, especially in busy industrial settings. Equipment must withstand varying conditions like temperature, moisture, and dust.

Factors that influence reliability include:

- Duty Cycle: This defines how often the motor can operate without overheating. Knowing the duty cycle helps in choosing the right motor for your workload.

- Environmental Conditions: If the equipment is working outside or in harsh areas, select motors designed for those conditions.

Regular maintenance can also increase reliability, ensuring your equipment performs well under stress.

Performance and Industrial Needs

Performance is determined by how well your lifting equipment meets industrial demands. This involves assessing lift capacity, speed, and control.

Things to consider are:

- Load Weight: Ensure your motor can handle the maximum load. Check the lifting capacity provided by the manufacturer.

- Speed Control: This feature provides flexibility in lifting operations, allowing adjustments for different loads.

Matching equipment specifications to your industrial needs ensures efficiency and safety. Always aim for a balance between power and performance to optimize your lifting tasks.

READ MORE : Adapting Your Marketing for Today’s Consumer